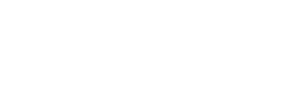

WOOD CHARCOAL CRUSHER

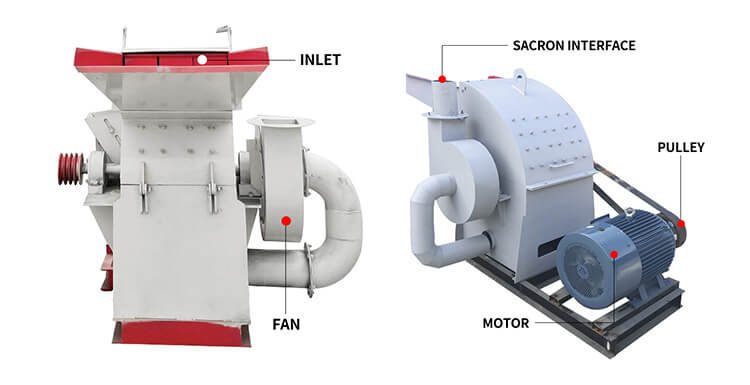

The charcoal crusher machine for charcoal is especially suitable for charcoal powder processing, it’s maked up by cutting device,crushing device and fan. It mainly processing wood charcoal,coconut shell, bamboo charcoal,peanut charcoal, carbonized wood chips or small wood log, etc.

The final discharged powder is from 80-100 mesh. Without drying can be sent to the crushing device for further crushing. It with high crushing ratio, equal product granularity, simple structure, reliable working condition, low consumption and convenient maintenance.

Working Principle of Charcoal Crusher Machine

Materials from the hopper into the crushing chamber, there have been high speed rotating hammer crushing blow, under the action of centrifugal force to break the material along the outer edge of the rotor, continuous by the hammer, tooth plate, screen film extrusion, collision, combat, rubbed and was quickly crushed,crushed powder after the centrifugal rotor by the pressure and suction force of the fan sent outside through the sieve, sieve the powder through repetition but on top process until the machine through the sieve was sent to the far outside.

1) Since hammers are cross and non-overlapping arrangement, and their width is greater than hammer frame and contour, they are ensured to participate in crushing by the full length of the rotor. And due to the hammerheads being arranged inactively, the energy consumption will reduce when the hammerheads crush materials, to improve the crushing efficiency.

2) Structure designing principle of this device is “stone to stone” coarse-crushing chamber, fine crushing chamber, impact chamber(composed of wedge adjustable impact plate and circular plate), and three discharging channels.

3) In the coarse crushing chamber, this crusher adopts the designing principle of “stone to stone”. That greatly reduces the hammer wearing. Besides, whether newly entering materials or ones in coarse and fine crushing chambers, they both can be discharged in time. That can greatly improve production capacity and reduce energy consumption.

Application

1. The small wood crusher is kind of special equipment in making superior quality wood powder (edible mushrooms), widely used for preparation department of paper-making , mushrooms, mechanism charcoal, chipboard, wood particle board, HDF, MDF. The raw materials are usually be logs,and tree branches. Moreover ,it is also can process a variety of materials, such as fodder, etc.

2. Wood crushers can also be used for fiber stalks such as bamboo, thatch, corn stalks, sorghum stalks, pine, wood, twigs, fir, bamboo, plant roots, stems, rice husks, corn cobs, bark and any other raw material. Material material.

3. The small wood crusher also can be used for the development of producing some raw materials, such as mushroom wood, shaving board, high density board, charcoal, etc.

Machine Parameters

|

Model

|

Power(kw)

|

Number of blades

|

Rotating speed(r/min)

|

Capacity(t/h)

|

|

500

|

22

|

4

|

2800

|

1-2

|

|

600

|

30-37

|

4

|

2400

|

1.5-2.5

|

|

800

|

45

|

4-6

|

2400

|

2.5-3.5

|

|

1000

|

55+5.5

|

4-6

|

2000

|

3-4

|

|

1200

|

75+5.5

|

9

|

2000

|

3-5

|

|

1500

|

90+5.5

|

12

|

2000

|

4-6

|

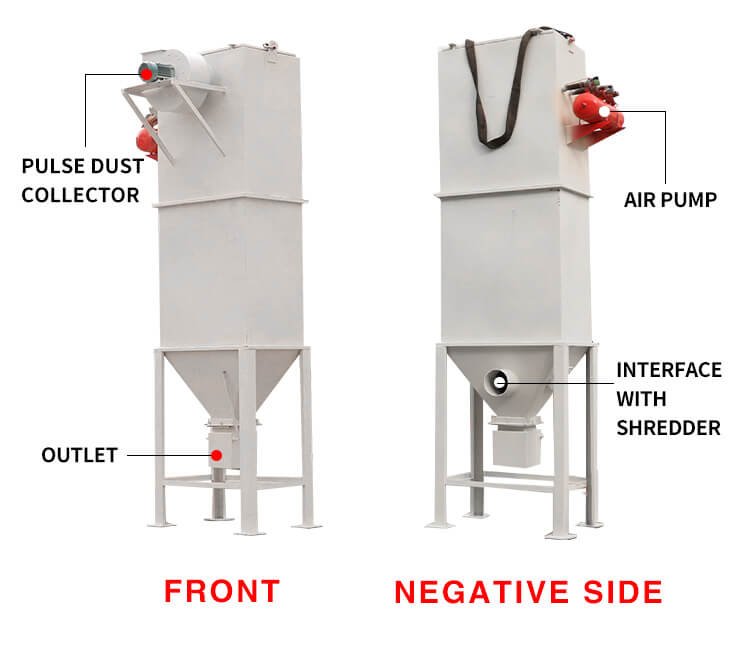

Production Line

The crusher adopts blade cutting and high-speed flow, collision and double crushing functions can be completed on one machine, and particles can be separated at the same time. During the cutting process, the rotor generates a high-speed airflow. As the cutting direction of the blade rotates, the material is accelerated in the airflow and repeatedly impacted to make the material double crush and accelerate the material crushing speed.

Customer site

We are a professional manufacturer of charcoal machine equipment. We provide customers with production lines and various accessories. Such as trolley, induced draft fan, burner, high-voltage electrostatic system, etc. Therefore, we can customize different sizes of equipment.

If you call or email us now to tell us your specific needs, we will develop solutions for you in a timely manner.