Brief Introduction

Coal briquette press machine can press charcoal powder, coal powder, dry powder, coke powder, carbon powder, iron scale, mineral waste residue, iron powder, various powder material and into different shape and size balls according to the different moulds. It is mainly used for fuel, boiler heating or for cooking and BBQ. The shapes can be in different forms of oval, egg, pillow, square ,etc. This machine is widely used in charcoal, coal industry and metallurgy industry.

Working Principle of Ball Briquette Press Machine

The main part of the charcoal briquette machine is a pair of rotating shafts of the same size, with many hemispherical sockets of the same size and regularly arranged on the surface.

The processed material will enter through the feed port and be squeezed into the hemispherical sockets on both sides under the action of its own gravity and the pressure of the rollers on both sides. The hemispherical sockets on both sides merge into a complete sphere, the raw materials inside will gradually be compressed, and finally form the coal ball briquette. With the further movement of the shaft, the formed coal ball falls from the discharge port.

The Structure of Ball Briquette Press Machine

The charcoal briquette forming machine mainly includes hopper, gear, press roller, conveyor belt, motor, speed controller, and other structures. Two of the gears drive two roller molds. Because the pressure rollers move towards each other, the two hemispheres can form a complete sphere.

Usage

●High output, high reliability and low energy consumption

●Relatively high working pressure, low vibration and stable operation

● A variety of sizes and shapes are available

● It has perfect effect for grinding hard and medium hard materials.

● The smart roller bearing lubrication system ensues its excellent performance the whole day.

● Compact steel body and reasonable price makes it and ideal choice for your own use or business.

Raw Materials & Finished Products

1. Coal/coke/charcoal powder.

a) Size of materials: less than 1mm, should be controlled between 30-40%; between 1-2mm, should be 30-40%; the max size should be no bigger than 3mm, with 20%.

b) Moisture of material: should be in 8-12%.

c) Not allowed: slad or other massive sundries with high hardness, or the roll and splindle will be damaged.

d) Agglomerant or other additives: should be prepared by users in accordance with coal type and the operating environment.

Machine Parameters

|

Model

|

Roller Diameter(mm)

|

Capacity(t/h)

|

Power

|

Reducer

|

|

290

|

290

|

1-2

|

5.5-7.5

|

350

|

|

360-2

|

360

|

2-3

|

7.5-11

|

350

|

|

360-4

|

360

|

2-3

|

11-15

|

400

|

|

450

|

450

|

4-5

|

22

|

400

|

|

550

|

550

|

5-8

|

37

|

500

|

|

650

|

650

|

8-10

|

45

|

650

|

|

800

|

800

|

15-20

|

90

|

850

|

|

1000

|

1000

|

25-30

|

110

|

1000

|

How to Use?

1. If you raw material is sawdust or rice husk or coconut shell.Use our carbonization stove to carbonize your raw material into charcoal.

2. The seond step:Use crusher to grind charcoal into powder.

3. Then use the Charcoal mixer to mix the charcoal powder with binder.

4. Put the starch and water into binder mixer , then mix them.

5. The final step:use our briquette machine to produce many different shapes briqette base on you need.

Charcoal Briquettes Machine Delivery

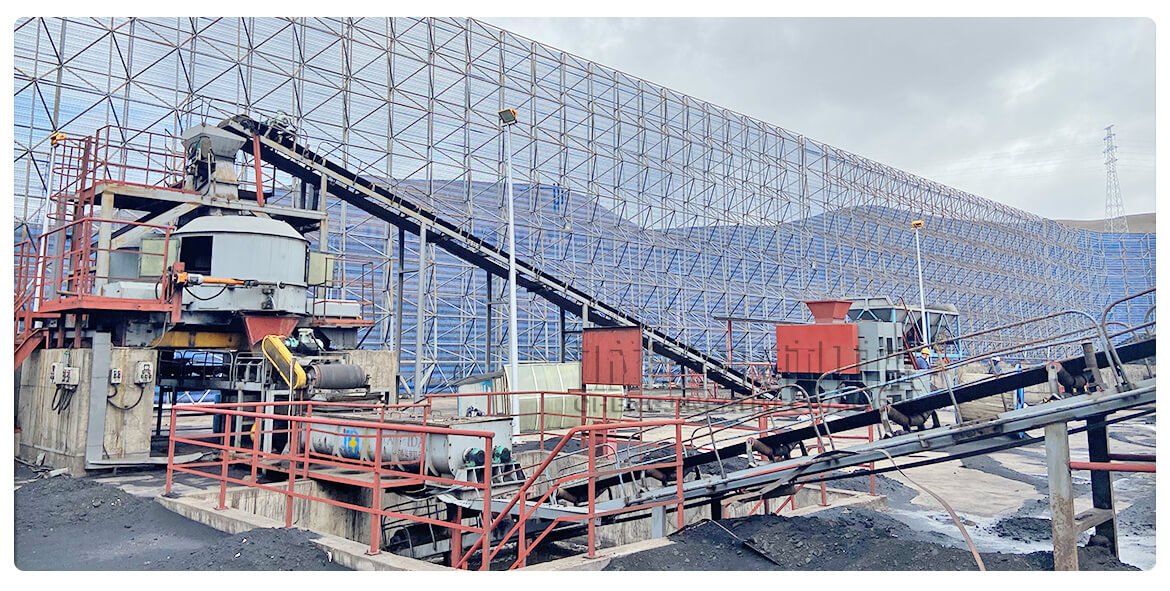

Customer site

We are a professional manufacturer of charcoal machine equipment. We provide customers with production lines and various accessories. Such as trolley, induced draft fan, burner, high-voltage electrostatic system, etc. Therefore, we can customize different sizes of equipment.

If you call or email us now to tell us your specific needs, we will develop solutions for you in a timely manner.