Краткое введение

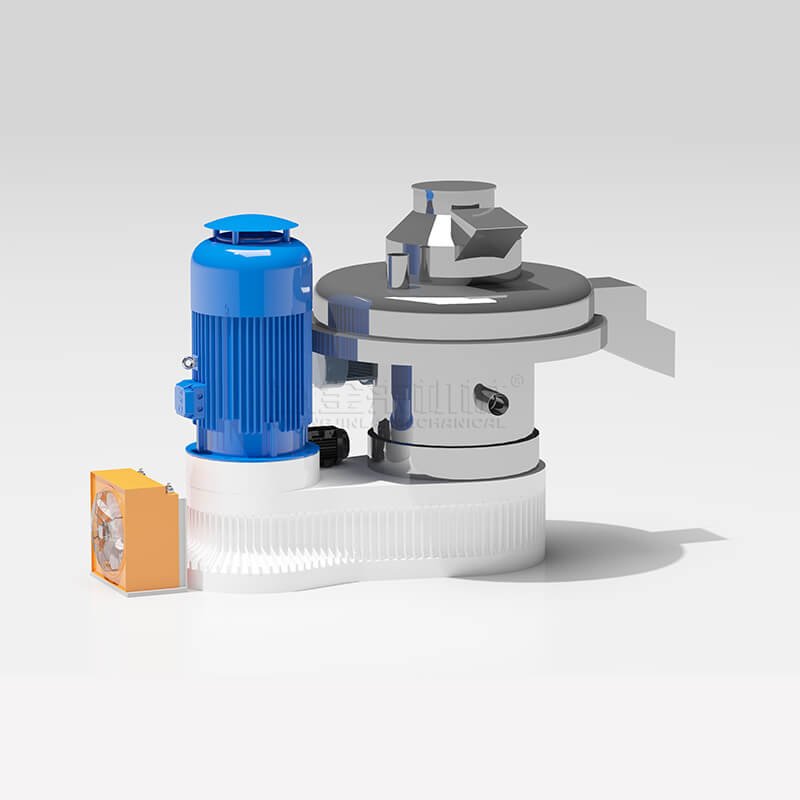

Машина для производства древесных гранул из биомассы - это производитель древесных гранул новой конструкции для производства топливных гранул из биомассы.. В основном подходит для гранулирования грубого волокна., такой как: древесная щепа, рисовая шелуха, стебли хлопка, хлопковая шелуха, сорняки и другие стебли сельскохозяйственных культур, бытовой мусор, отходы пластмасс и отходы заводов. Он также подходит для гранулирования материалов с низкой степенью адгезии и трудно поддающихся формованию., такие как грануляция, пресс-блок и гранулятор, а также может использоваться для низкотемпературной грануляции биологических бактериальных удобрений., органические удобрения и комплексные удобрения.

Принцип работы

Подробная информация о продукте

Пресс-форма из нержавеющей стали

Цельная матрица для цементации из нержавеющей стали,высокая износостойкость, хорошая стабильность,увеличение площади разгрузки,увеличить емкость и снизить затраты. Двойной слой,обе стороны можно использовать, снизить стоимость.

Ролик

Сименс Мотор

Двигатель машины для производства древесных гранул имеет частоту, с толстой медной катушкой, Он не сгорит из-за мгновенного тока.

Машина для производства пеллет из биомассы отвечает потребностям различных отраслей промышленности

Какое сырье можно использовать для прессования пеллет?

Оборудование для производства древесных гранул может прессовать различное твердое и мягкое сырье., например, дерево, опилки, оливковый, сосна, сельскохозяйственная солома, рисовая шелуха, скорлупа арахиса, стебель кукурузы, бамбук, трава, например, и т. д.. Если размер вашего сырья слишком велик, вам понадобится дробилка для дерева, чтобы сделать его подходящего размера.

Как прессовать древесные пеллеты?

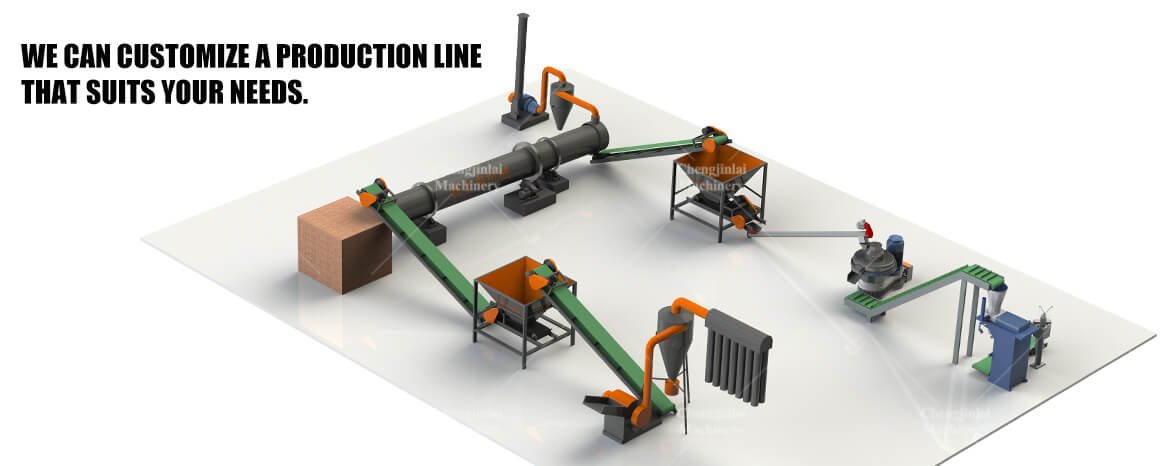

Основной процесс изготовления древесных гранул, как показано ниже.: