Экструдер для производства древесноугольных брикетов

Машина для производства брикетов может экструдировать различные порошковые материалы в брикеты., например угольный порошок, угольный порошок, и т. д.. Оба могут производить древесный уголь для барбекю.(форма цилиндра, шестиугольная форма, четырехугольная форма) ,уголь для кальяна(кубическая форма, круглая форма полоски, шестиугольная форма полосы).

Принцип работы экструдера для древесноугольных брикетов

Экструдер для древесного угля использует принцип винтовая экструзия для прессования угля/древесноугольного порошка в формованные брикеты. После того как угольный порошок засыпается в загрузочный бункер, он продвигается вперед к разгрузочному отверстию брикетировочной машины с помощью винта. От винтовой камеры к форме, пространство становится меньше. Под огромным давлением, древесный уголь проходит через формы и, наконец, принимает определенные формы..

Использование

1.Прессование угольной пыли в сплошной или полый цилиндр, квадрат, Брикет шестиугольной формы для барбекю.

2.Разный диаметр готовых брикетов соответствует различным требованиям рынка..

3.Подходит для различных типов углеродного порошка.;неважно, лесные отходы, отходы сельского хозяйства, углеродная пыль.

Различные методы резки

1. Пневматическое режущее устройство

Этот тип пневматической резки обычно устанавливается на выходе машины для производства древесноугольных брикетов и оснащен индукционным устройством.. Когда угольный стержень достигает определенной длины, оно автоматически обрежется.

2. Машина для резки кубического угля

Это устройство для кубической резки используется для резки кубического угля.. Разрезанные угольные стержни проходят через эту машину и превращаются в угольные блоки одинаковой формы и размера..

3. режущее устройство с ЧПУ

Это наша новейшая машина для резки угля.. Он принимает интеллектуальную систему управления, Длина резки угольных стержней может свободно регулироваться и использоваться для резки угольных стержней различной формы..

Сырье & Готовая продукция

Эта машина может работать практически со всеми видами биомассы.: опилки, стружка, древесные отходы, филиалы, рисовая шелуха, скорлупа арахиса, багасса, барда, ватные палочки, кукурузные палочки, пшеничная солома, рисовая солома и другие культуры. это и сырье в первую очередь обуглиться, а затем спрессоваться в угольные стержни.

Помимо древесного угля и угля, эта экструдерная машина также может производить брикеты из кокса, осадок, оливковые выжимки, коровий навоз, и т. д.. Для изготовления качественных брикетов, Размер порошка древесного угля должен быть менее 3 мм., и влага вокруг 20%. Для удовлетворения требований различных клиентов, формы формы могут быть шестиугольный, квадрат, круговой, и т. д.. Более того, клиенты могут выбирать производство полых или твердых брикетов, а диапазон диаметров брикетов составляет 3-50 мм..

Параметры машины

|

Модель

|

СМ140

|

СМ160

|

СМ180

|

|

Емкость

|

1-1.5т/ч

|

1.5-2т/ч

|

2-3т/ч

|

|

Власть

|

15кВт

|

22кВт

|

22квартал-30 квартал

|

|

Размер подачи

|

≤5 мм

|

≤5 мм

|

≤5 мм

|

|

Содержание влаги

|

25%-35%

|

25%-35%

|

25%-35%

|

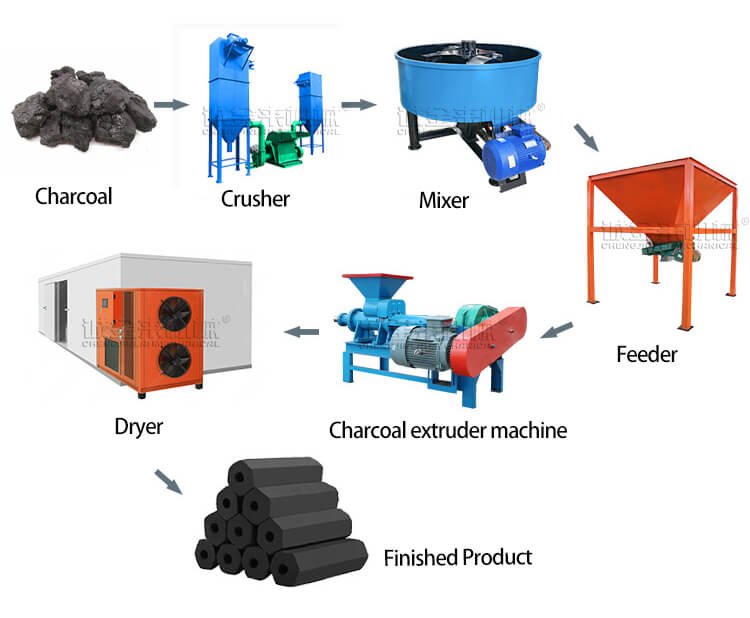

Как использовать?

1. Если сырьем являются опилки, рисовая шелуха или скорлупа кокосового ореха. Используйте печь для карбонизации карбонизировать сырье в древесный уголь.

2. Второй шаг:Использовать дробилка измельчить уголь в порошок.

3. Затем используйте уголь миксер смешать порошок древесного угля со связующим веществом и водой.

4. Использовать машина для экструдирования древесного угля производить брикет-основу различной формы под собственные нужды.

5. Готовую продукцию сушите сушилка или естественно

Заводская площадка доставки

Сайт клиента

Мы являемся профессиональным производителем оборудования для древесного угля.. Мы предоставляем клиентам производственные линии и различные аксессуары.. Такие как троллейбус, вентилятор с принудительной тягой, горелка, высоковольтная электростатическая система, и т. д.. Поэтому, мы можем изготовить оборудование разных размеров.

Если вы позвоните или напишите нам сейчас, чтобы сообщить нам о ваших конкретных потребностях, мы разработаем для вас решения в кратчайшие сроки.