Mesin Ekstruder Briket Arang

Mesin briket dapat mengekstrusi berbagai bahan bubuk menjadi briket, misalnya bubuk arang, bubuk batubara, dll.. Keduanya bisa menghasilkan arang BBQ(bentuk silinder, bentuk heksagonal, bentuk segi empat) ,arang shisha hookah(bentuk kubik, bentuk strip bulat, bentuk strip heksagonal).

Prinsip Kerja Mesin Extruder Briket Arang

Mesin ekstruder arang mengadopsi prinsip ekstrusi sekrup untuk mengompres batubara/bubuk arang menjadi briket berbentuk. Setelah bubuk arang dituangkan ke dalam feeding hopper, itu didorong maju ke lubang pembuangan mesin briket dengan sekrup. Dari ruang sekrup hingga cetakan, ruang menjadi lebih kecil. Di bawah tekanan yang luar biasa, arang melewati cetakan dan akhirnya terbentuk menjadi bentuk tertentu.

Penggunaan

1.Menekan debu arang ke dalam silinder padat atau berongga, persegi, briket bentuk segi enam untuk barbekyu.

2.Diameter briket akhir yang berbeda memenuhi kebutuhan pasar yang berbeda.

3.Cocok untuk berbagai jenis bubuk karbon;tidak peduli limbah hutan, limbah pertanian, debu karbon.

Metode pemotongan yang berbeda

1. Alat pemotong pneumatik

Mesin pemotong pneumatik jenis ini umumnya dilengkapi pada pintu keluar mesin briket arang dan dilengkapi dengan alat induksi.. Ketika batang batubara mencapai panjang tertentu, itu akan otomatis terpotong.

2. Mesin pemotong arang kubik

Alat pemotong kubik ini digunakan untuk memotong batubara kubik. Batang batubara yang dipotong melewati mesin ini menjadi balok batubara dengan bentuk dan ukuran yang seragam.

3. Perangkat pemotong CNC

Ini adalah mesin pemotong batubara terbaru kami. Ini mengadopsi sistem kontrol cerdas, panjang pemotongan batang batubara dapat diatur secara bebas dan dapat digunakan untuk memotong batang batubara dengan berbagai bentuk.

Bahan Baku & Produk Jadi

Hampir semua jenis bahan biomassa tersedia untuk mesin ini: serbuk gergaji, serutan, limbah kayu, cabang, sekam padi, kulit kacang, ampas tebu, anggur, batang kapas, batang jagung, jerami gandum, jerami padi dan tanaman lainnya. Ini Dan bahan bakunya terlebih dahulu diolah dikarbonisasi dan kemudian ditekan menjadi batang karbon.

Selain arang dan batu bara, mesin ekstrusi ini juga dapat menghasilkan briket dari kokas, lumpur, pomace zaitun, kotoran sapi, dll.. Untuk membuat briket berkualitas baik, ukuran bubuk arang harus kurang dari 3mm, dan kelembapan di sekitarnya 20%. Untuk memenuhi kebutuhan pelanggan yang berbeda, bentuk cetakan bisa heksagonal, persegi, bundar, dll.. Lebih-lebih lagi, pelanggan dapat memilih untuk memproduksi briket berongga atau padat dan kisaran diameter briket adalah 3-50mm.

Parameter Mesin

|

Model

|

CM140

|

CM160

|

CM180

|

|

Kapasitas

|

1-1.5th

|

1.5-2th

|

2-3th

|

|

Kekuatan

|

15kw

|

22kw

|

22kuartal-30 kuartal

|

|

Ukuran makan

|

≤5mm

|

≤5mm

|

≤5mm

|

|

Kadar air

|

25%-35%

|

25%-35%

|

25%-35%

|

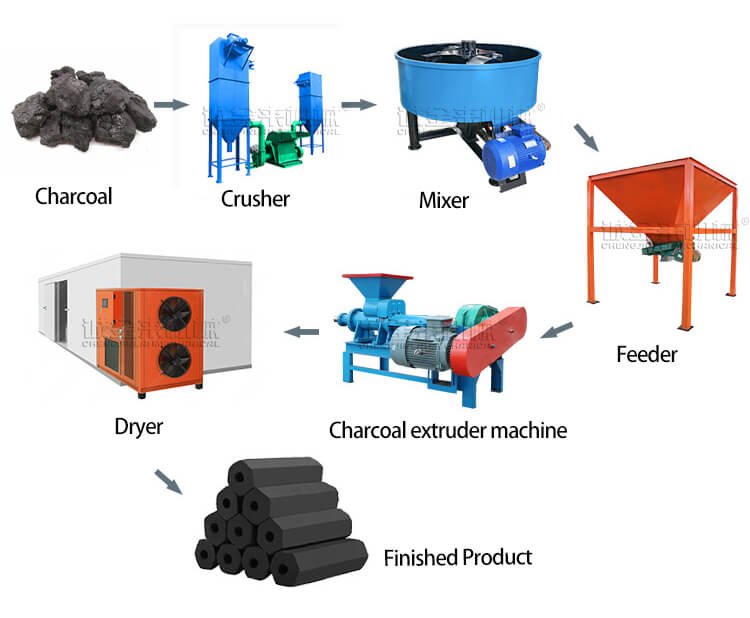

Cara Menggunakan?

1. Jika bahan bakunya serbuk gergaji atau sekam padi atau tempurung kelapa.Gunakan tungku karbonisasi untuk mengkarbonisasi bahan mentah menjadi arang.

2. Langkah kedua:Menggunakan penghancur untuk menggiling arang menjadi bubuk.

3. Kemudian gunakan Arang pengaduk untuk mencampur bubuk arang dengan bahan pengikat dan air.

4. Menggunakan mesin ekstruder arang untuk memproduksi berbagai bentuk briket berdasarkan kebutuhan sendiri.

5. Keringkan produk akhir dengan pengering atau secara alami

Situs pengiriman pabrik

Situs pelanggan

Kami adalah produsen profesional peralatan mesin arang. Kami menyediakan jalur produksi dan berbagai aksesori kepada pelanggan. Seperti troli, kipas angin yang diinduksi, pembakar, sistem elektrostatik tegangan tinggi, dll.. Karena itu, kami dapat menyesuaikan berbagai ukuran peralatan.

Jika Anda menelepon atau mengirim email kepada kami sekarang untuk memberi tahu kami kebutuhan spesifik Anda, kami akan mengembangkan solusi untuk Anda tepat waktu.