Continuous Smokeless Biomass wood Carbonization Furnace Manufacturing Charcoal Plant Coal Carbonization Furnace environmental for dry distillation and oxygen-free carbonization of small carbon-containing wood materials such as shell sunflower seed shells under high temperature conditions in the carbonization machine.

Continuous Smokeless Biomass wood Carbonization Furnace Manufacturing Charcoal Plant Coal Carbonization Furnace environmental can carbonize different materials into charcoal, como aserrín, astillas de madera, cáscara de arroz, sugarcane bagasse,etc.. Finished charcoal can be sold in the market directly, or deep processing into bbq charoal, shisha charcoal, etc.. The whole set mainly contains carbonization furnace, gasification furnace, charging part, discharging part, fan, etc.

The equipment is safe and environmentally friendly, with stable operation and long service life.

1.Central control can be designed according to the customer’s request, which can separate the operator and machine.

2.A large number of new materials and new processes are selected, patented technology design, precision production, and after a lot of practical tests, every detail is pursued for perfection to ensure the quality of each set of equipment.

3.Power supply section has a standardized control system, Configured with sealing system, iginition alarm equipment system to ensure the environmental cleanliness and production safety.

This machine is suitable for all kinds of agricultural and forestry biomass charring making. For example: wood shavings, serrín, wood chip, cáscara de arroz, cotton stalk, crop straw, bean Stalks, paja, corn straw, soybean straw, sorghum straw, rape straw, peanut, tallo de girasol, grass and shrub branches, bamboo truncated, sprue, bagasse, cáscara de coco, walnut shell, apricot shell, hemp, bambú, eucalyptus, fungus residue, medicinal residue, residuo de furfural, coffee grounds, cáscara de palma, Serrín, Cotton Stalk, Coffee Husk, Peanut Shells, Pine Needle, Rice Husk, Sugar Mill Waste.

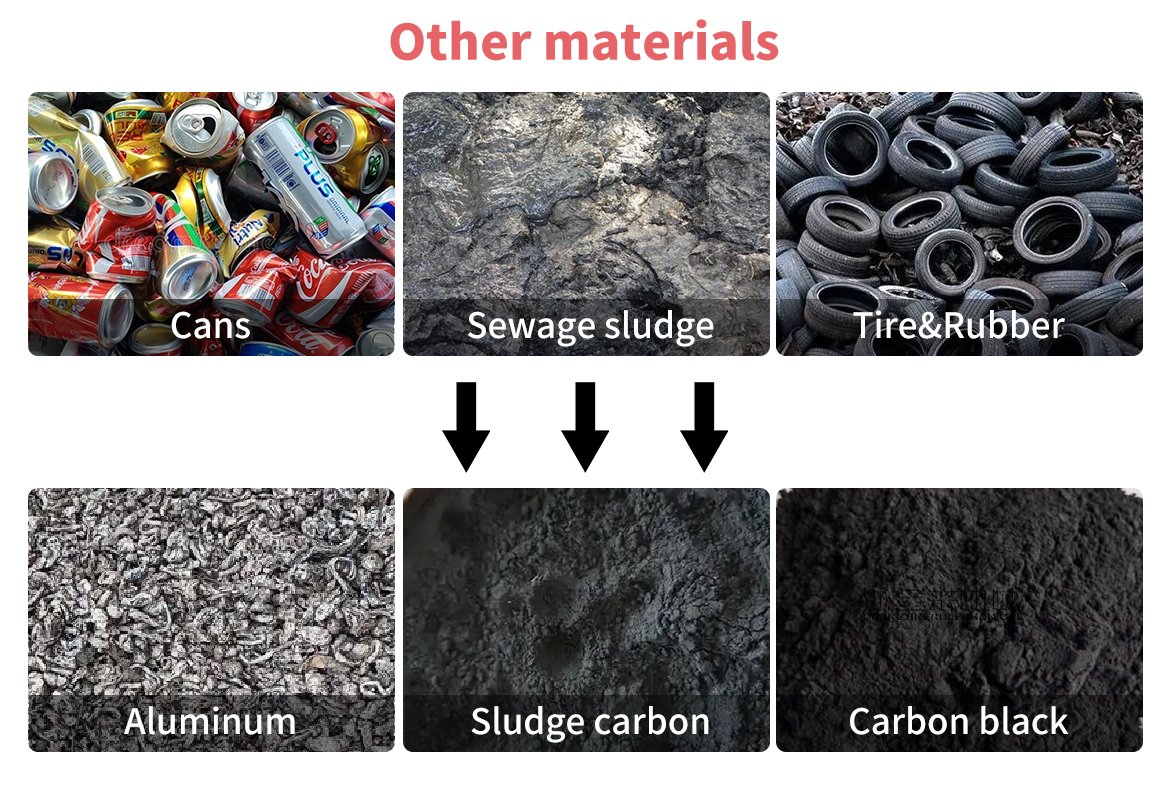

larger (50mm or more) raw materials, such as aluminum capacitors, wires, waste clothes, wood branches, cans, Pop can(Compacted or not compacted), Carbonized aluminum can, Cable wire(lly-illed cables or ordinary wire), Copper wire, Electric capacity, Carbonized capacitance etc.,need to be shredded and then carbonized. If the moisture exceeds 30%, it needs to be dried in advance.

|

End Products

|

Area

|

Usages

|

|

Carbón

|

Daily life

|

• widely used as the fuel of BBQ.

|

|

• used as the fuel in other industries.

|

||

|

Agriculture

|

• attach heavy metal to improve the quality of the soil.

|

|

|

Industry

|

• can be reprocessed into activated carbon.

|

|

|

• used for construction bricks with clay.

|

||

|

• widely used as fuel in industries such as steel and iron factories, ceramics, etc..

|

||

|

Biogas

|

Daily life

|

• widely used as fuel.

|

|

Agriculture

|

• greenhouse agriculture heating.

|

|

|

Industry

|

• used as fuel for heating or drying.

|

|

|

• can be used for the generator to get electricity.

|

||

|

Wood vinegar, Tar

|

Industry

|

• used as permeability-reducing agent for construction.

|

|

• the great materials in shipbuilding and paint industry.

|

||

|

• used as raw materials in chemical and medicine field.

|

||

|

Agriculture

|

• Anti-insect fungicide, pesticide neutralization, soil conditioner.

|

|

|

• used as plant nutrition regulates auxin or insecticide.

|

Carbonization furance charcoal making equipment production line processing:

1.Carbonize the raw materials(Continuous carbonization furnace,it is suitable for small piece size raw material)

2.Crush carbonized raw matrial into charcoal powder(Trituradora)

3.mix the charcoal powder(Whell mixer)

4.Extrud the charcoal powder into shape you need(Coal charcoal extruder machine)

5. Secador con bomba de calor para secar el producto terminado formado. (ya que el contenido de humedad del producto terminado durante este proceso de producción será alto, el producto terminado debe secarse nuevamente)

6.packing finished product (Elija la máquina empacadora adecuada según la forma del producto terminado)

Por favor díganos sus materias primas y requisitos específicos., Y podemos configurar la línea de producción según sus requisitos.!