Печь карбонизации представляют собой специальное сырье для входа и выхода тележек и передовую технологию процесса сухой карбонизации горячим газом., использование уникального дымового газа карбонизации. Технология обратного прожига, в полной мере использовать дымовые газы, образующиеся в процессе карбонизации, удовлетворить тепловые потребности самой печи карбонизации, значительно увеличить скорость карбонизации, скорость карбонизации увеличился с 80% более чем 95%, и прост в эксплуатации, безопасность и защита окружающей среды, высокая эффективность производства, можно сэкономить много энергии, является идеальным оборудованием для карбонизации длинностержневого материала биомассы..

Принцип работы печи горизонтального карбонизации

Печь карбонизации использовать карбонизация сухой перегонкой и карбонизация воздушным потоком методы. Затем нагревают и разлагают древесину в условиях без кислорода или с низким содержанием кислорода., из древесины получается древесный уксус, древесная смола, и другие ингредиенты. Более того, выхлопная труба печи карбонизации с горизонтальным воздушным потоком может вовремя собирать дымовые газы и откладывать вредные вещества..

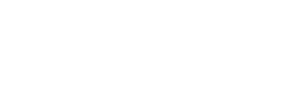

Сырье & Готовая продукция

Почти вся биомасса можно превратить в уголь, например, скорлупа арахиса, скорлупа кокоса, древесина, биомасса, некоторые культуры, бамбук, древесные отходы, филиалы, стволы, журналы, лаять, пни, корни, деревянный поддон, опилки, стружка, древесная щепа, фруктовое дерево, рисовая шелуха, кукурузный початок, скорлупа арахиса, остаток фурфурола, ракушка пальмы, полукокс и т.д..

Горячий в использовании ?

1. Проверьте,приятельриалы соответствовать стандарту. The содержание воды меньше 20%, и размер около 50 мм. В противном случае, мы можем предоставить вам дробилки и др.да.

2. Откройте дверцу печи, и поместите материал внутрь напрямую; или вы можете положить материал на железнодорожный вагон, чтобы отправить материал во внутренний бак.

3. Запечатать печь, и проверь клапана и прочее.

4. Разожгите печь и добудьте древесный уголь. Этот шаг, есть горючий газ производить, и этот газ можно направить в нижнюю часть горловины, чтобы машина нагрелась..

5. После угля закончено и охлаждено, затем воспользуйтесь железнодорожным вагоном, чтобы доставить уголь.

Параметры машины

|

Модель

|

Размер внутреннего цилиндра (Диаметр x Длина)

|

Размеры (длина*ширина*высота)

|

Масса

|

Выход

|

|

CJL-50

|

0.5*0.75м

|

1.1*0.7*1м

|

130кг

|

50-100кг

|

|

CJL-250

|

1*1.5м

|

1.8*1.2*1.6м

|

450кг

|

200-300кг

|

|

CJL-500

|

1.5*1.5м

|

1.8*1.7*2.2м

|

1000кг

|

500-600кг

|

|

CJL-1000

|

1.5*3м

|

3.8*1.8*2.4м

|

2800кг

|

1500кг

|

|

Размер машины может быть настроен в соответствии с требуемой производительностью..

|

||||

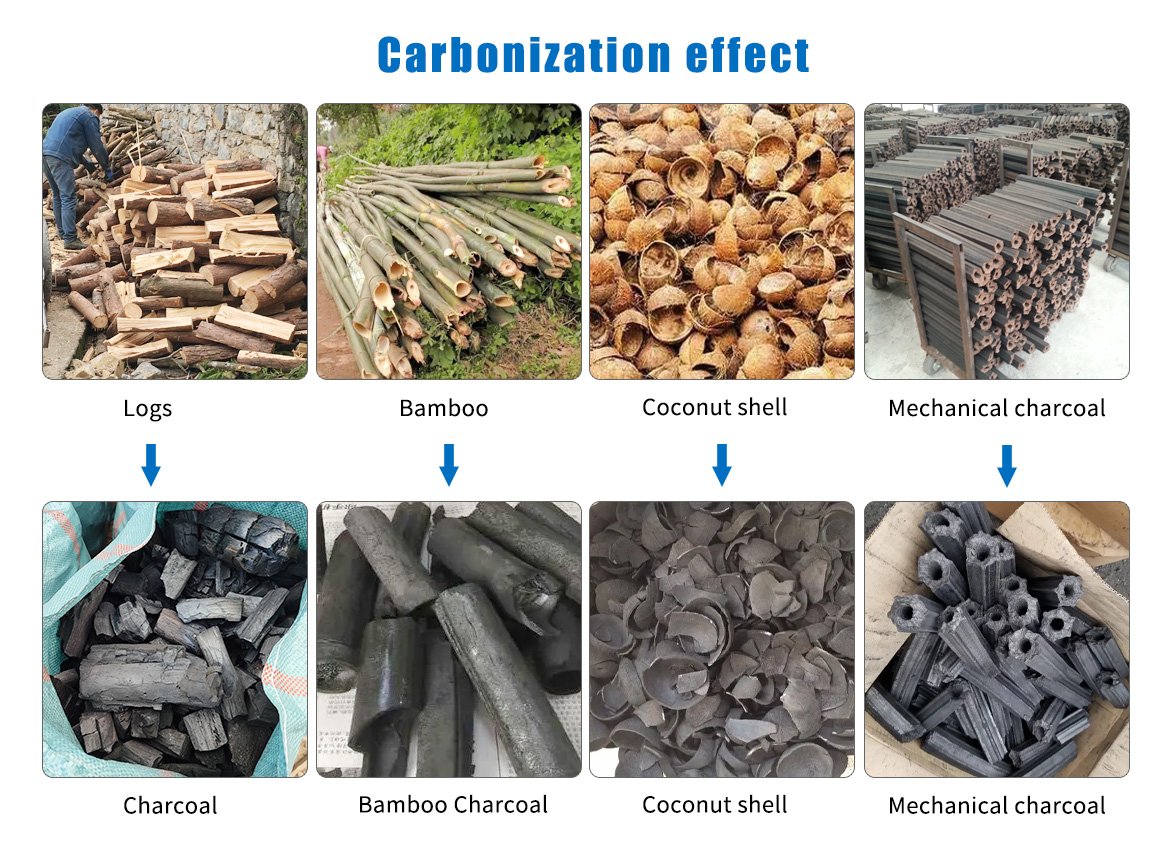

Производственная линия

Производственная линия Ⅰ : Дробление — Сушка — Брикетный пресс — Карбонизация брикета в древесный уголь

Или, ты можешь сначала карбонизировать сырье

Производственная линия Ⅱ:

1.Кокосовая скорлупа, древесина, бамбук и другая биомасса обуглившийся в древесный уголь с помощью печи карбонизации и входа в подъемник и резервуар для хранения. В зависимости от сырья заказчика, вы можете выбрать печь непрерывного карбонизации, горизонтальная печь для производства древесного угля и подъемная печь для карбонизации.

2.древесный уголь можно измельчить в угольный порошок шлифовальная машина без пыли.

3.Помешивать угольный порошок и клей с помощью миксера.

4.Порошок древесного угля можно превратить в мяч, цилиндр, столы и куб. на машине для брикетирования

5.Введите сушилка путем сушки.

Мы являемся профессиональным производителем оборудования для древесного угля.. Мы предоставляем клиентам производственные линии и различные аксессуары.. Такие как троллейбус, вентилятор с принудительной тягой, горелка, высоковольтная электростатическая система, и т. д.. Поэтому, мы можем изготовить оборудование разных размеров.

Если вы позвоните или напишите нам сейчас, чтобы сообщить нам о ваших конкретных потребностях, мы разработаем для вас решения в кратчайшие сроки.